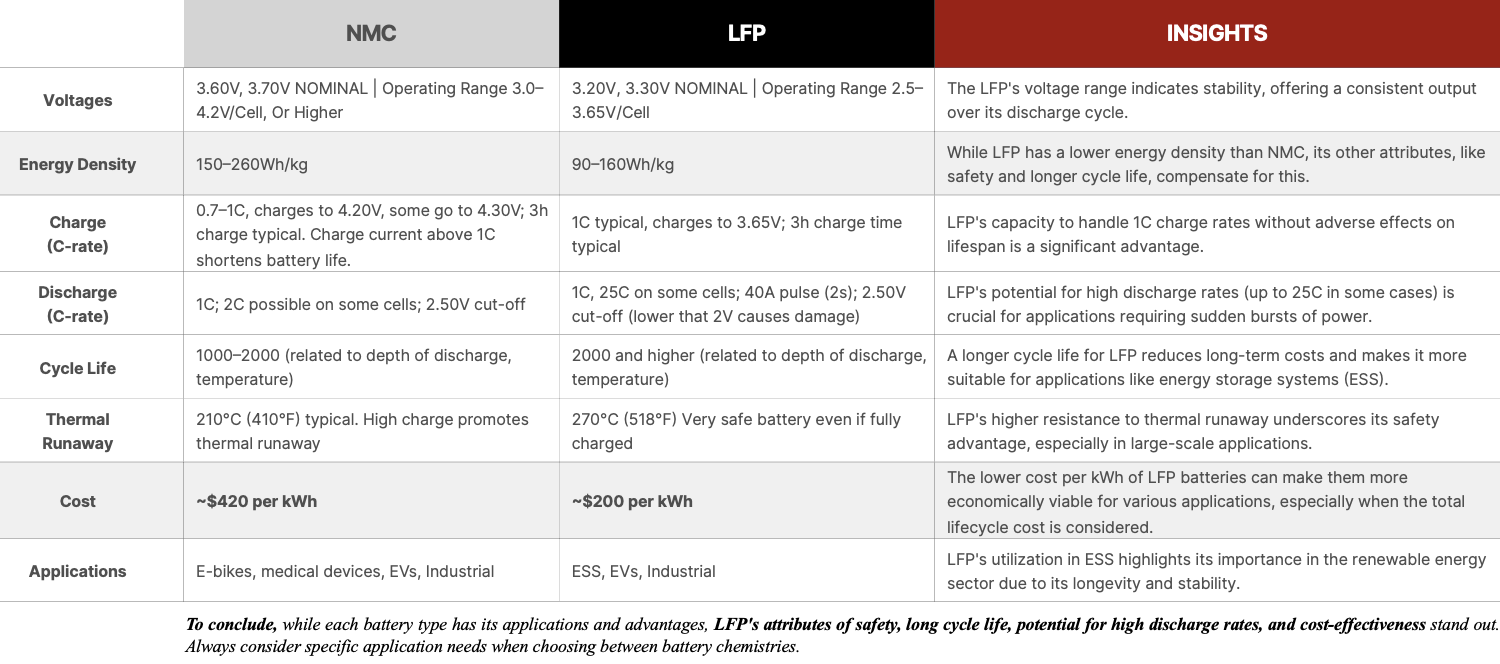

NMC vs. LFP

A Comparative Analysis of Lithium-Ion Battery Technologies

Key Performance Insights: Voltage, Energy Density, Charge/Discharge Rates, Cycle Life, Safety, and Cost Considerations

Strengthening U.S. Battery Production: A Strategic Shift

Global battery manufacturing is currently dominated by China, South Korea, and Japan, with China alone accounting for an overwhelming 893 GWh of global capacity. This dominance is a result of China's early prioritization and substantial investment in battery manufacturing infrastructure. In contrast, the United States holds just 6% of the global battery production capacity, producing 70 GWh.

To close this gap, the U.S. is leveraging the Advanced Manufacturing Production Credit (45X), which offers incentives of up to $45 per kWh of battery capacity, aimed at bolstering the downstream EV battery supply chain. This initiative is part of a broader strategy to reduce reliance on foreign suppliers, particularly from China, and ensure greater energy security and supply chain resilience.

By diversifying and localizing supply chains, automakers in the U.S. will not only be better equipped to handle global disruptions but also meet growing domestic and international demand. Furthermore, these efforts align with ambitious climate goals and address human rights and environmental concerns associated with overseas mining practices.

With increasing domestic investments and a focus on strengthening local supply chains, North America is on track to become the second-largest player in global battery production. These advancements mark a pivotal step toward achieving energy independence, fostering economic growth, and securing a more sustainable future.

Key Advantages of LFP Batteries

Safety, Longevity, and Sustainability

Why Lithium Iron Phosphate (LFP) Batteries

Are Leading the Future of Energy Storage and EV Technology

LFP Battery Advantages

1. Superior Safety & Stability

Highly resistant to thermal runaway, minimizing fire and explosion risks.

Stable chemical structure reduces degradation and ensures consistent performance.

Better temperature tolerance, allowing reliable operation even in high-heat environments.

2. Extended Cycle Life & Reliability

Thousands of charge/discharge cycles before significant capacity loss.

Flat discharge curve ensures stable voltage output throughout most of the cycle.

Less prone to swelling, maintaining structural integrity over time.

3. Environmental & Ethical Benefits

No heavy metals or toxic materials, making LFP batteries eco-friendly in both production and disposal.

Low cobalt content, avoiding ethical and environmental concerns tied to cobalt mining.

4. Cost-Effectiveness & Efficiency

Lower total lifecycle cost due to exceptional durability and longevity.

Low self-discharge rate, making it ideal for applications where the battery may remain unused for long periods.

5. High Performance & Versatility

High current rating, supporting power-intensive applications like EVs and industrial motors.

Widely used in renewable energy storage, electric vehicles, UPS systems, and more.

LFP batteries continue to be a top choice for energy storage solutions, offering a balance of safety,

efficiency, and sustainability that makes them ideal for a wide range of applications.